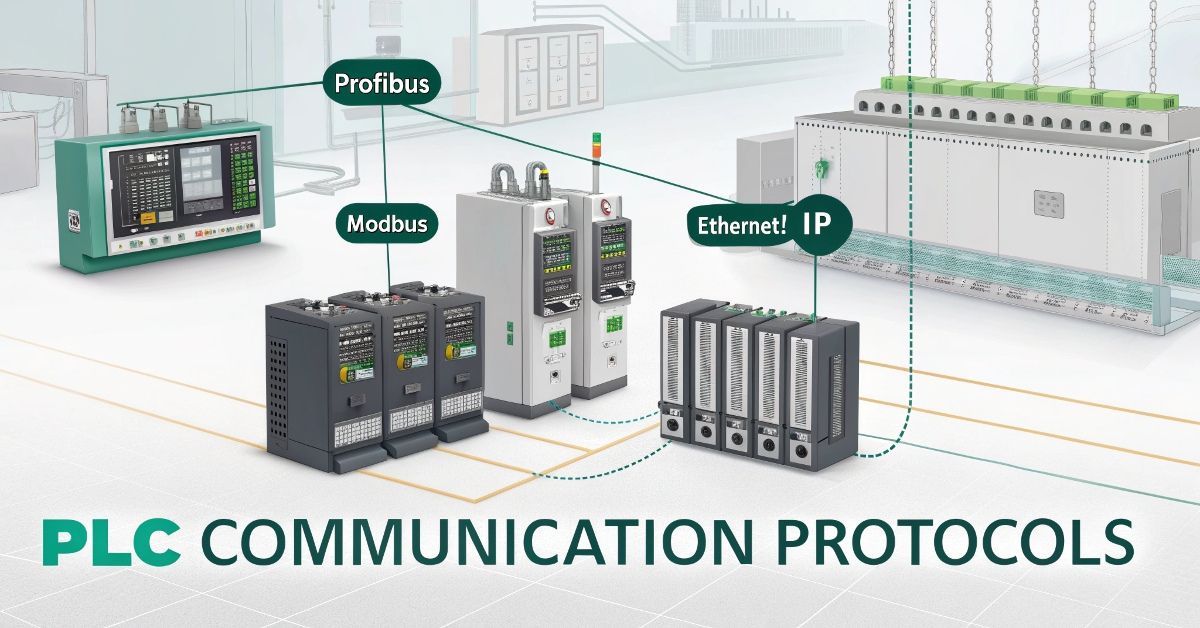

PLC Communication Protocols Explained

The functionality of PLCs requires them to establish communication with one another as well as other devices. The devices exchange data through signals and execute operations in live time. When communication between hardware components is not proper the automation system becomes unintelligible. The usage of certain communication standards surpasses that of others. Modbus together with … Read more