The term SCADA appears complex but it carries a straightforward meaning. Supervisory Control and Data Acquisition is the abbreviation that describes this system. SCADA operates as a monitoring and control platform which enables distant management of industrial machines. The system functions as a factory’s visual system and manual control combined into one computer display. Additionally the system executes basic decisions before human intervention.

Various industries utilize SCADA systems for power generation plants, water purification systems, and chip-producing factories. The existence of the machine’s control system remains unknown to most people even though it functions in their vicinity. That’s wild, right? Fielding information on operation has the same impact as witnessing wizardry behind the magic. Learning this system does not require engineering expertise. The following demonstration will explain why this technology should interest you as your potential superpower.

What Is SCADA and Why Is It Crucial in Industrial Automation?

A manufacturing control room functions as the foundation of the SCADA system. The system performs monitoring duties on machines while collecting their data to generate signals that control equipment operations. Software performs all operations that would previously require switch flipping and gauge reading and alert shouting from the control room operators. To me, it operates as a silent controller which drives noisy mechanical instruments. The lack of this system would lead factories towards complete darkness.

A single malfunction in a manufacturing facility costs thousands of dollars due to its operation. Before equipment fails both literally and financially SCADA intervenes through its systems. Having would be equivalent to working with an unbelievable organizational and never-tiring assistant without sleep or the need for coffee. The system reduces operational times while eliminating waste while maintaining continuous operation. In the current era of speed and intelligence the technology remains vital according to my evaluation.

The Main Components of a SCADA System

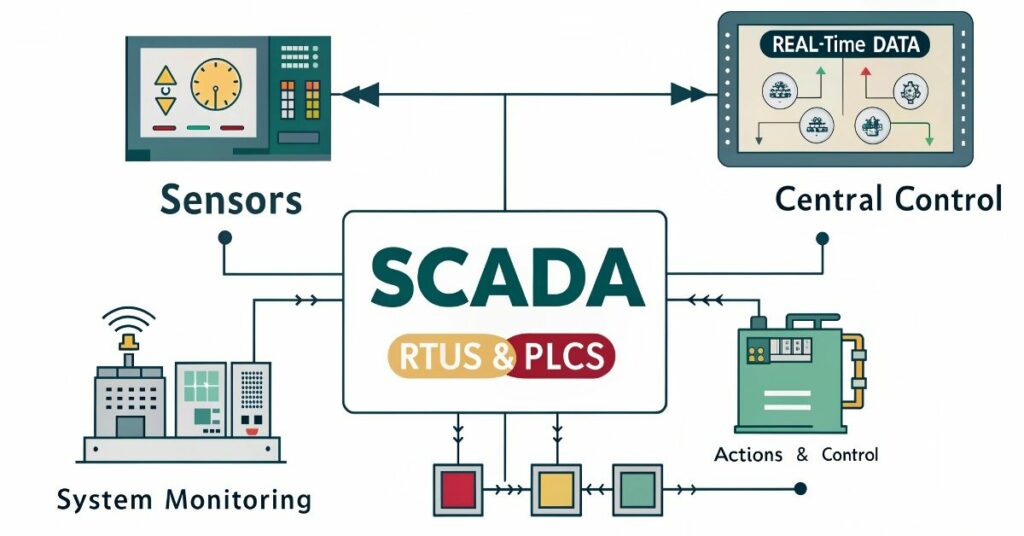

Field Devices and Sensors:

Scada systems monitor operations through these devices which serve as their sensors and detectors. The sensors function outside their designated machines by retrieving information regarding pressure and temperature and speed measurements. I view them as small spies because they constantly observe without any eye movement. Through live information input into the system users can make decisions swiftly. No guessing. No delay.

RTUs/PLCs and Central Systems:

The system performs its calculations in this area. The sensor data processed through RTUs and PLCs turns into activation instructions. The system operates through switch flips and valve openings together with similar operational functions. Afterward the central system both displays the data through screens and creates system records for everything. I think the system acts as a single entity which combines biological processes of brain and nervous system functions. The system connects everything and functions as the control mechanism that monitors all operations while preventing any missing information.

How SCADA Systems Work: A Step-by-Step Overview

Field devices with sensors monitor machines by collecting similar data as digital stethoscopes measuring heart pulses. The data collection system goes through RTUs or PLCs which extract the information while executing commands when needed. The devices might act to stop a motor operation while making adjustments to a valve. The central system receives all information which gets displayed on a screen. System operators monitor current operations and will intervene if they notice abnormal conditions. The process operates as a continuous series where operators watch, decide, take action and start the pattern anew.

SCADA in Action: Real-World Industry Applications

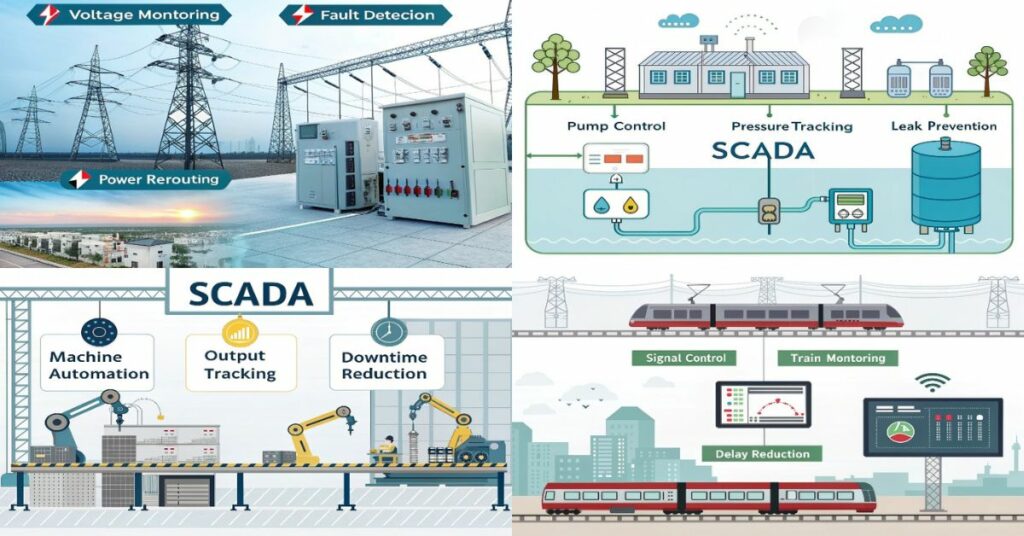

The application of SCADA technologies exists in every corner of the modern world. Power grids depend on to maintain electricity supply and identify equipment issues ahead of electrical hazards. Water facilities depend on to maintain uninterrupted fluid flow of safe water. The system operates traffic management by handling signals to prevent rush hour congestion. The quiet operation of this technology astonishes me since it powers numerous common systems. SCADA operates without much attention while playing a vital role in our functional infrastructure.

The same control objectives guide industry-specific applications of systems since they aim for operational control while reducing risks and costs.

| Industry | What SCADA Does |

| Energy | The device checks voltage levels and spots faults then directs power distribution |

| Water & Wastewater | Pressure tracking and pump control functions together with leak prevention capabilities |

| Manufacturing | The technology tracks production, controls equipment, and reduces downtime |

| Transportation | Controls signals, monitors trains, reduces delays |

Why SCADA Knowledge Is Essential for Engineers and Technicians?

Engineers along with technicians need to understand SCADA effectively for their modern era roles. Caretaking no longer focuses on machine troubleshooting but extends to system administration. The modern industrial sector relies on it as its critical operational component. People without SCADA understanding will remain behind in their field. The ability to diagnose quickly belongs to engineers but the practice of smooth operation remains the responsibility of technicians. The knowledge of systems enables professionals to carry out both tasks effectively. Problem-solving becomes their expertise instead of mere equipment maintenance after acquiring this skill.

Here’s why it’s so important:

- It helps spot and fix issues before they escalate.

- Learning about SCADA standards provides organizations performance enhancements and better work output.

- During complex systems management one must give priority to automation practices.

- The maintenance functions achieve system stability while decreasing operational stoppages that result in financial losses.

How to Start Learning SCADA: Tools, Resources, and Tips

Natural entry into SCADA only demands suitable tools together with practical experience. Begin with foundational explanations about sensors together with PLCs and their controlling systems’ operation. Make use of educational tutorials then read technical guides while practicing with simulation software systems. The best way to learn? Get your hands dirty. Your work assignments will involve PLC and components where you will experience live operations while working with S7 1200 and S7 300 and Indusoft. That’s where it clicks. The real experience surpasses videos and books to become the best way for learning to happen. Failure comes with trying new things while questioning everything you learn as part of the training process.

FAQ’s

How does SCADA apply in everyday operations?

The substance operates in power plants alongside water treatment facilities and manufacturing plants together with traffic systems to sustain smooth operations.

What are the reasons for engineers and technicians to study SCADA?

This essential skill for automation enables problems to be resolved rapidly and intelligently with reduced breakdown occurrences.

How can I start learning SCADA?

Teach basic concepts first before guiding students towards engineering practical’s with S7 1200, S7 300 and Indusoft equipment to achieve tangible experience.

Conclusion

The technology behind might seem technological at first but it proves to be transformative after mastering the basics of operation. SCADA operates as a system that protects industry operation efficiency and security while enhancing their smart functionality. Studying systems creates valuable advantages because it enables you to solve hardware faults as well as construct operational frameworks and investigate industrial internals.

Every learner should consider studying SCADA because it represents a worthwhile path toward growth in automation and industrial technology fields. Available tools with a manageable learning difficulty deliver significant benefits. Work with genuine projects and touch and observe systems while taking logical risks. Learning occurs at its peak when people explore the evolution of operations.