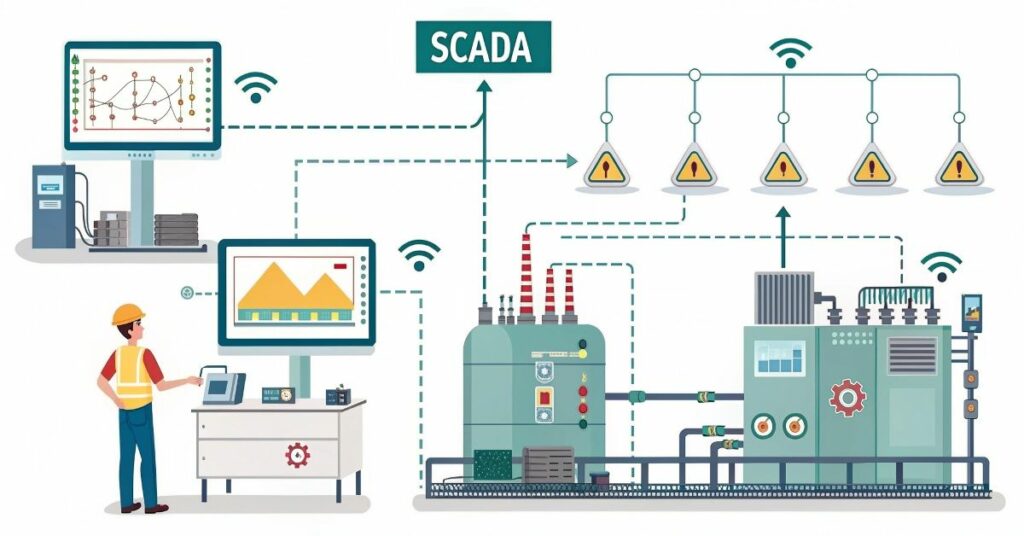

Someone who manages SCADA system operations holds the position of SCADA Engineer. The implementation of SCADA systems enables organizations to exercise command and diagnostic capabilities for operating machines present in power plants, factories and water treatment facilities. Safe system operations result from the SCADA Engineer’s implementation of setup and maintenance work on these systems.

Delivery systems at large factories operate continuously while machines run unmanned 24 hours per day. People require methods to determine both system malfunctions and regular operational status. The entry point of SCADA Engineers occurs within these operations. Their work involves creating as well as overseeing systems which gather present-time operational information to trigger warning signals when equipment malfunctions occur. SCADA Engineers contribute to cost savings and survival protection in addition to performance efficiency.

The work of SCADA Engineers depends on hardware as well as software platforms. Engineering staff typically operate with sensors together with computers and control systems. Industrial operations success and security depend on their essential work at all times.

Introduction to SCADA Systems

SCADA represents a method that allows humans to monitor equipment operations as well as control various processes. The SCADA system obtains data from sensors that get transmitted to computers. People obtain this data to verify operational health. The systems become essential components that enable supervisory control in various facilities starting from power plants through factories to water treatment facilities.

Through the implementation of SCADA systems workers gain immediate access to recognize operational issues. The system generates an alert when any problem occurs. The system allows faster problem solving together with maintaining system safety. The efficiency of work combined with financial cost savings emerges from SCADA system operations. The technology serves crucial purposes in multiple modern industrial applications.

Who is a SCADA Engineer?

SCADA represents a method that allows humans to monitor equipment operations as well as control various processes. The SCADA system obtains data from sensors that get transmitted to computers. People obtain this data to verify operational health. The systems become essential components that enable supervisory control in various facilities starting from power plants through factories to water treatment facilities.

Through the implementation of SCADA systems workers gain immediate access to recognize operational issues. The system generates an alert when any problem occurs. The system allows faster problem solving together with maintaining system safety. The efficiency of work combined with financial cost savings emerges from SCADA system operations.

Key Responsibilities of a SCADA Engineer

The primary duty of a SCADA Engineer includes multiple essential responsibilities. The SCADA system functions are verified by these maintenance technicians through their work. The engineer plans the system development and builds it before conducting analysis for testing. The maintenance of secure and problem-free operations falls under their responsibility.

Key responsibilities:

- Design and set up SCADA systems

- Monitor system performance

- Fix errors and solve problems

- Update software and hardware

- Keep data safe and secure

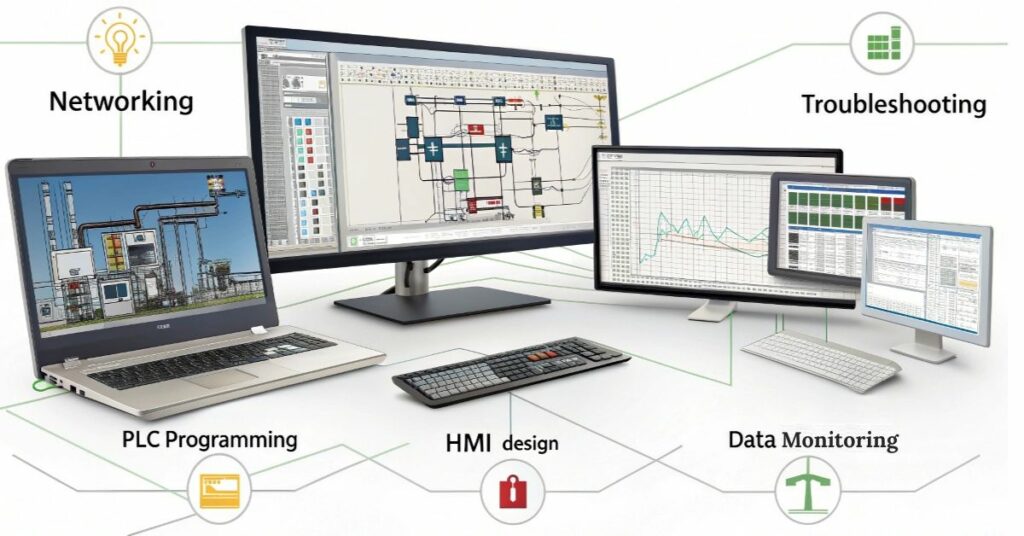

Essential Skills and Tools Used

The profession of SCADA Engineering demands both computer-based technical expertise and behavioral skills. Understanding computers and networks and control systems must be mastered by such professionals. The two key skills that a SCADA Engineer needs are excellent problem-solving abilities and strong communication skills. They excel at locating and resolving technical problems through their acquired skills.

Special tools and software form part of the instrument set used by SCADA Engineers. The tools assist engineers in system development tasks including observation and operation control. Secondary sources indicate a few vital tools which SCADA Engineers commonly apply through this simple layout:

| Skill/Tool | Purpose |

| SCADA Software | To control and monitor systems |

| PLC (Programmable Logic Controller) | To automate machines |

| HMI (Human-Machine Interface) | To show system data on screens |

| Networking Skills | To connect all system parts |

| Troubleshooting Skills | To find and fix problems fast |

Industries that Employ SCADA Engineers

Procurement and implementation personnel with expertise in SCADA technology serve various sectors of the economy. The engineers assist organizations which operate using machines together with automated systems. Engineering staff members maintain the system safety and operational efficiency.

SCADA Engineers include:

- The company needs to both operate and support systems that run industrial facilities.

- The organization should ensure safe, smooth, and incident-free operations.

- The IT staff handles logging, maintenance, and software updates.

- Experts must excel in problem-solving and control systems.

- Your organization should adopt IoT with AI capabilities and cloud-based solutions.

Career Path and Educational Requirements

SCADA functions as a system that enables human operators to monitor equipment operations and make changes through remote control methods. The system gathers information from sensors while verifying health conditions of systems. The implementation of SCADA systems exists in power plants and factories together with water treatment facilities.

The system immediately warns workers about problems thus enabling swift resolutions and protecting personnel safety. The system serves both to increase operational efficiency and reduce expenses which is why it is essential for contemporary industries.

Future Trends in SCADA Engineering

Modern industries require rapid transformation of SCADA systems to fulfill their operational needs. Current developments of Internet of Things (IoT) and Artificial Intelligence (AI) as well as cloud computing systems transform SCADA solutions into advanced efficient monitoring platforms. Such new technology capabilities allow for instant data acquisition while supporting predictive equipment upkeep and better business decision procedures.

The adoption of Industry 4.0 by industries leads to increased integration of SCADA systems while enabling their performance on advanced operations. Cloud-based platforms provide scalability together with flexibility which enables both remote control and observation of systems.

FAQ’s

The responsibilities of a SCADA Engineer require defining?

As a SCADA Engineer one designs and implements SCADA systems that monitor and control industrial processes in facilities such as power plants and factories.

Which abilities does someone require to develop into a SCADA Engineer?

For effective work as a SCADA Engineer one requires expertise in computers and networks and control systems combined with problem-solving abilities and communication competencies to maintain operational efficiency.

What transformations are present in the current development of the SCADA industry?

The SCADA field is evolving with advancements in IoT, AI, and cloud computing, making systems smarter, more efficient, and capable of predictive maintenance and remote control.

Conclusion

The operations of industry depend heavily on SCADA Engineers for smooth production. They handle the development as well as supervision and upkeep of SCADA systems to control machine and process operations. The essential role these specialists perform benefits the operations of energy production and manufacturing and water treatment facilities.

The advancing nature of technology will require SCADA Engineers to have increasingly complex roles. The combination of IoT and AI with cloud computing is transforming SCADA systems into more efficient operation. Modern SCADA engineering presents new professional opportunities which also demand advanced work skills from engineers in this field.