The functionality of PLCs requires them to establish communication with one another as well as other devices. The devices exchange data through signals and execute operations in live time. When communication between hardware components is not proper the automation system becomes unintelligible.

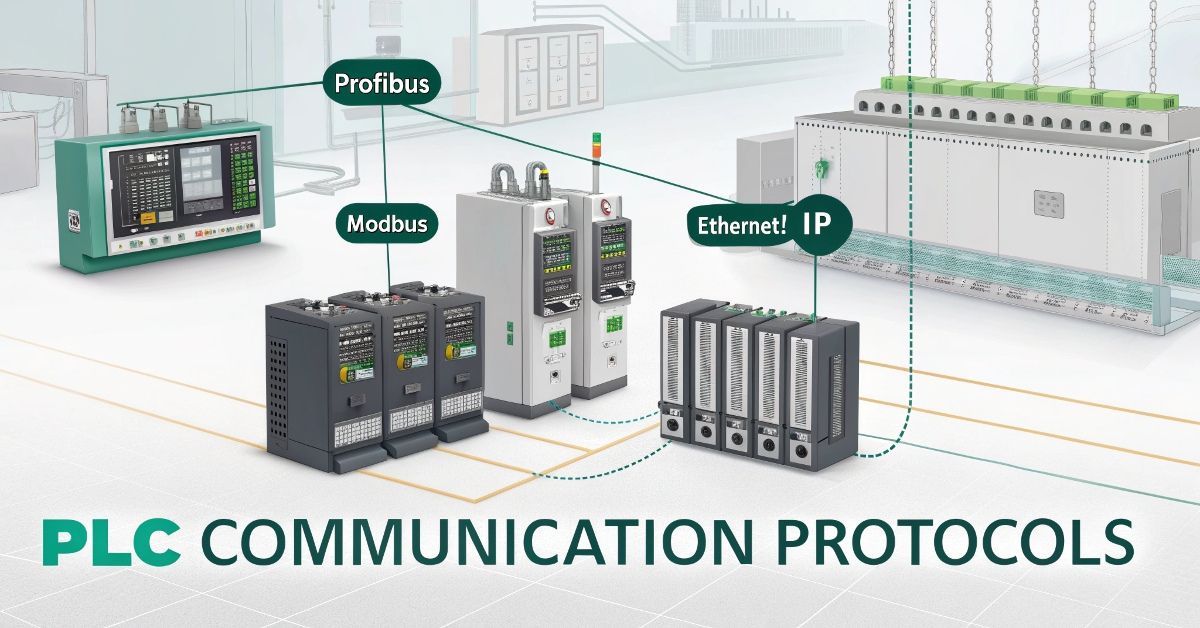

The usage of certain communication standards surpasses that of others. Modbus together with Ethernet/IP and Profibus emerge frequently as vital communication systems. The communication standards between PLCs possess distinct characteristics regarding their operational tempo along with specific configuration parameters. Different industrial communication protocols have distinct features which make them suitable for varying systems so it becomes necessary to understand their distinctions.

Your choice of protocol determines how much time and effort as well as funding costs will be saved. Your system’s dimensions together with processing requirements and device connections define which protocol delivers the best results according to my assessment. With appropriate guidance the selection process becomes quite straightforward.

What Are PLC Communication Protocols?

Machines use communication protocols as their fundamental methods to exchange messages. The protocols determine how devices exchange information and establish common data-sharing protocols and synchronization methods. The fundamental element of each automated system exists in communication protocols. The absence of protocols would leave sensors and PLCs and controllers simply stranded while being unaware of each other.

During industrial operations active communication protocols cannot accept any form of mixed signals. Standardized communication plays a vital role because of its importance for system operations. This enables machines to collaborate no matter their operating brands or configuration. Proper protocols produce reduced mistakes during operations and facilitate faster maintenance procedures while streamlining operational functions.

The Importance of Protocols in Industrial Automation

All communication channels between PLCs and HMIs and SCADA systems need to maintain clear data exchange. The smooth transmission of data depends on protocols which intermediary different system components. The system becomes unstable quickly when protocols are absent machines stop communicating which causes confusion to overcome the operation. The suitable configuration between systems ensures every component maintains connectivity resulting in efficient process execution.

I strongly believe that protocols serve purposes beyond enabling device communication because they strengthen the overall industrial operations. The reliability of systems increases as well as their ability to incorporate diverse brands working together. Their architecture enables live system management without limitations even when operating sophisticated systems. Industrial automation achieves a massive improvement with this level of consistency.

Overview of Common Protocols: Modbus and Ethernet/IP

The simplicity of Modbus turns it into an outstanding solution. The protocol has existed since years but continues performing essential tasks without any issues. For basic duties such as motor control and sensor evaluation Modbus serves well according to my view. This protocol does not require advanced hardware while also having a straightforward installation process. The widespread device support for Modbus continues because of its basic operational nature.

The Ethernet/IP system represents an advanced solution with high-speed capabilities. Standard Ethernet protocols power this system through its industrial features. From my perspective the technology works best when big systems require instant dependable message exchange. The system operates complex data and multiple devices and real-time control tasks effortlessly and without failing.

Key highlights:

Modbus:

- Easy to use

- Great for simple data exchange

- Works on serial or TCP/IP networks

Ethernet/IP:

- Fast and scalable

- Built for real-time control

- Ideal for large, modern systems

Comparing Protocol Performance and Use Cases

All protocols deliver different functionality levels. Organizations require their protocols to perform either quickly or maintain stability. The combination of speed and scalability makes Ethernet/IP the winning network communication solution. Modbus delivers reliable performance at reduced speed which adapts to a wide range of equipment. Using compatible protocols between devices leads to project success therefore selecting one that works with all your devices makes sense.

Each application protocol shows maximum effectiveness at varying performance levels. I consider Modbus to be the most suitable approach for monitoring applications and basic machine networks. The time-sensitive nature of production lines together with its busy operations makes Ethernet/IP the suitable protocol choice. The selection of the correct choice depends on your system requirements.

| Protocol | Speed | Scalability | Best Use Case |

| Modbus | Low to Medium | Limited | Remote monitoring, legacy systems |

| Ethernet/IP | High | Excellent | High-speed production, real-time control |

Integration Challenges and Best Practices

The process of making various pieces of equipment communicate proves quite challenging. Heterogeneous protocols cause both sluggish communication speeds and complete interruptions between systems. Network congestion emerges as a major problem since excessive system traffic leads to slowing performance or complete failure. The lack of proper system connectivity creates frustration because the devices fail to communicate effectively.

The implementation requires creativity to succeed. Senior Management should focus on established intelligent planning methods. Gateways act as bridges which link protocols that have different communication methods. Proper configuration of devices should happen right after initial setup. The system requires protocol converters to maintain continuous synchronization when necessary. Brief initial configuration work will result in substantial later savings on maintenance efforts.

Choosing the Right Protocol for Your PLC System

Every system has different needs. Some need speed, others need compatibility. One should analyze hardware systems together with supported vendor protocols as well as anticipated system growth. Your current selection of a flexible system will prevent major problems during later development.

Wishing to make an appropriate decision start by using this basic framework. Your main objective should begin the decision process between speed-focused and reliability-centered and user-friendly setup solutions. Implement this requirement compared to the established protocol capabilities. The most effective approach for selecting a suitable protocol involves maintaining equilibrium between present requirements alongside future projections.

FAQ’s

What is a PLC communication protocol?

The standard method for PLC data exchange with HMIs and SCADA systems and other PLCs exists as PLC communication protocols.

Why are protocols like Modbus and Ethernet/IP important in automation?

Real-time device communication remains reliable through these protocols which enable joint control and monitoring activities within industrial facilities.

How do Modbus and Ethernet/IP differ?

In addition to supporting sophisticated applications, Modbus can be implemented easily using Ethernet/IP.

Conclusion

Selecting an appropriate PLC communication protocol represents the most essential factor for success. Your system functions optimally through this choice which decreases operational interruptions and unites all system components. Completion of straightforward work requires Modbus while Ethernet/IP provides fast control depending on your installation needs.

Think long-term. Establishing an appropriate protocol selection will reduce future expenses and stress as well as shorten project completion times. Planning in advance along with protocol compatibility testing and selection of an expandable communication standard delivers sufficient value for system success. It is necessary to use this method when implementing intelligent automation.