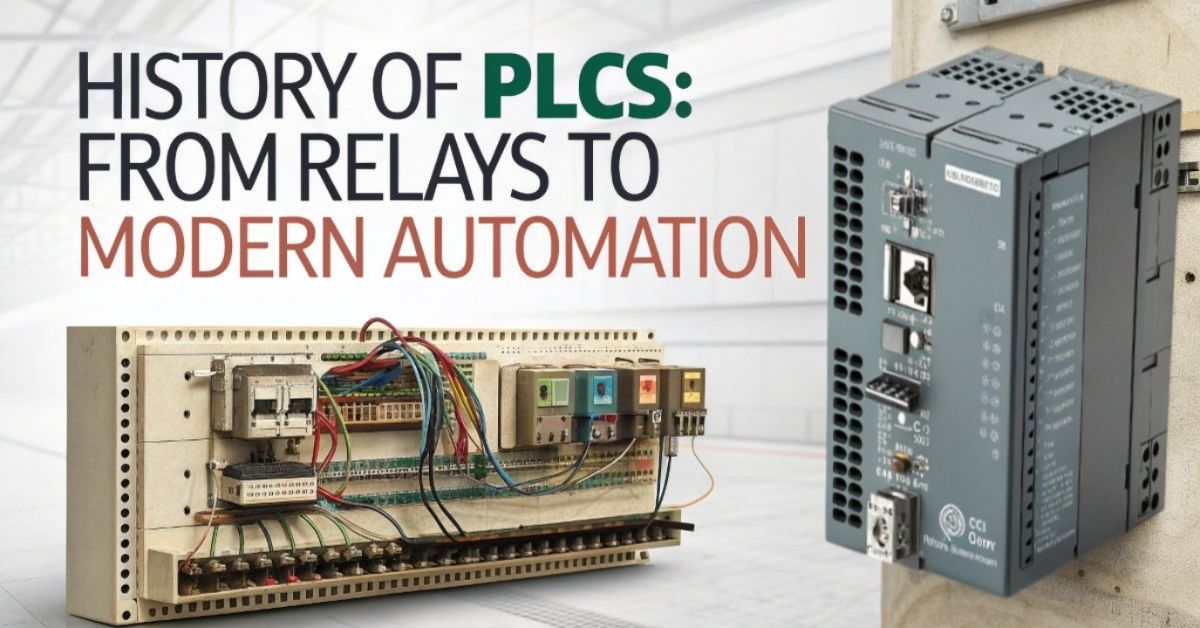

History of PLCs: From Relays to Modern Automation

PLCs have established a remarkable progression throughout their development history. The beginning of PLC development started when factories utilized basic relays and mechanical switches. The industrial sector shifted towards progressively smarter control methods because traditional solutions proved inadequate after many years. The development of the first authentic PLC system, which became a major milestone, came … Read more