Ladder Logic in PLC Programming is a simple visual language that looks like electrical relay circuits. Pictures and symbols are used instead of complicated computer codes. Because of this, beginners find it simple to learn and follow the instructions.

It is a key part of industrial automation. To manage machines, factories, power plants, and assembly lines all use it. Automated systems would not work smoothly or safely if ladder logic was not used.

It is remarkable because it is simple to learn and very effective. You can manage all sorts of systems using only a few commands. It makes tasks faster, decreases mistakes, and ensures that they are reliable.

Table of Contents

ToggleIntroduction to Ladder Logic

Ladder Logic was designed to perform in the same way as electrical relays. It depends on symbols and steps that form an image of a ladder. Each step is made up of instructions. As a result, it is simple to understand and fast to put together control logic.

Nowadays, PLCs use SCADA to control different machines and systems. Automation helps in many places, from packaging to water treatment. Its structure and reliability are why the tool is trusted by many industries.

Why Use Ladder Logic in PLCs?

Working with Ladder Logic is simple since it makes use of a visual layout. It is possible for engineers and technicians to quickly set up and change control systems. The way it is displayed looks familiar to people with experience in electricity. Therefore, it is put into use in factories and control rooms.

It also simplifies the process of finding and fixing problems. It is easy to follow the path of each logic. Whenever there is a problem, it becomes quickly visible. Due to this, the amount of downtime goes down and the systems work without issues.

Basic Elements of Ladder Logic

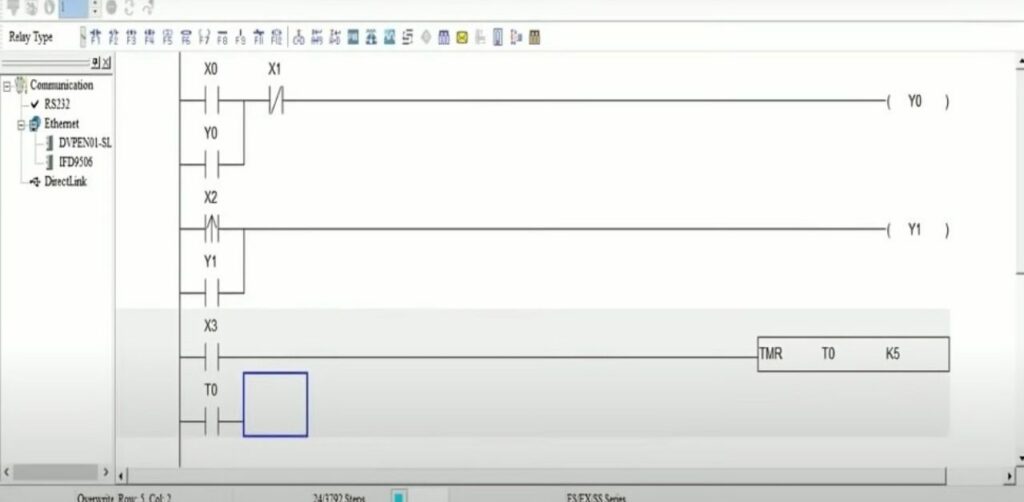

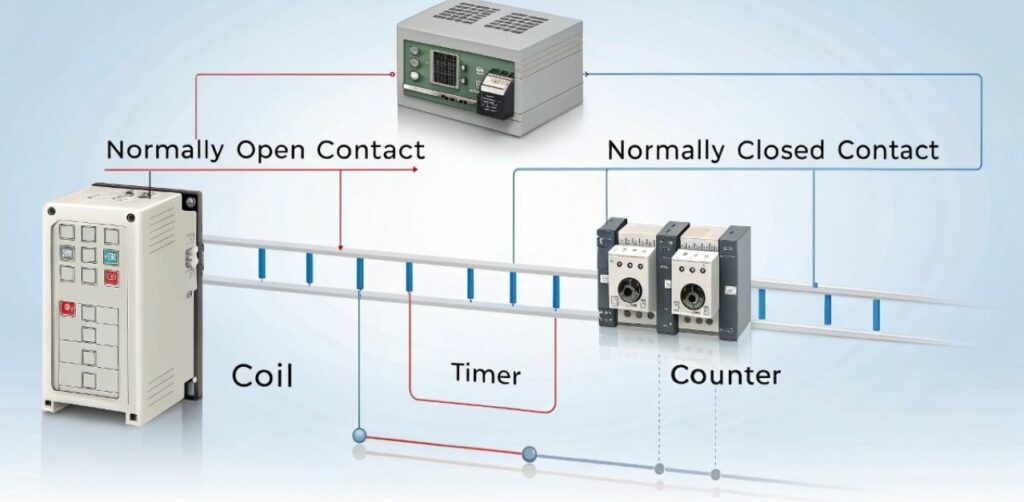

To make control logic, Ladder Logic relies on contacts, coils, timers, and counters. They all come together to manage the beginning, ending, or running of a process. Every part has a specific role and goes smoothly into the ladder rung. This supports the creation of systems that are able to change and remain dependable.

The process works the same way as reading a circuit diagram from left to right. The PLC evaluates each rung starting with the top and moving to the bottom and then from left to right. Because the logic is straightforward, it is easy to understand and solve issues.

Key elements include:

- Contacts – Represent input conditions (like switches or sensors)

- Coils – Represent output actions (like turning on a motor or light)

- Timers – Delay actions or keep them running for set times

- Counters – Track events or counts in a process

How Ladder Logic Works in Real Applications?

Ladder Logic goes through each step one after another. It analyses the inputs from sensors or switches and then determines which outputs should be used. It takes place very quickly, happening many times every second. Therefore, systems are prepared to act fast and in the proper way.

It affects many industries even when you may not realize it. It is used in many different places, for example, on conveyor belts, in elevators, and during packaging. Ladder Logic is capable of providing exact controls and timing to make these systems work smoothly. This is the reason why it is frequently used in real-world applications.

Ladder Logic Examples for PLC Programming:

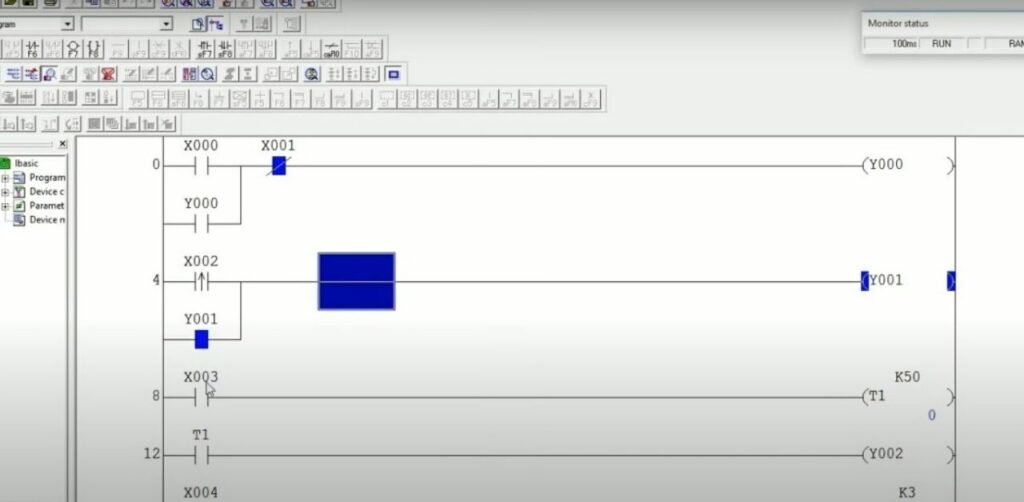

🟢 1. Start/Stop Motor Control (Latch/Unlatch Logic)

Purpose: Control a motor using a start and stop button.

Logic:

- Start Button (NO) → turns on the motor.

- Stop Button (NC) → stops the motor.

- Uses a latch (seal-in) to keep the motor running after start is pressed.

Stop

| Start |—-| |—-+——|/|—-+–( ) Motor

| Motor |—-| |—-|

🟢 2. Timer Example – Delay Start of a Motor

Purpose: Start the motor after a 5-second delay once the start button is pressed.

Logic:

- Timer starts when button is pressed.

- After 5 seconds, motor turns on.

| Start |—-| |———( ) Timer (T1)

[Preset: 5s]

| T1.DN |—-| |———( ) Motor

🟢 3. Light ON/OFF with Toggle Button

Purpose: Toggle a light on and off with a single push button.

Logic:

- Each press of the button toggles the state of the light (ON).

| Button |—-| |—-[One Shot]—-( ) Toggle Bit

Toggle Bit OFF

| Toggle Bit ON |—-| |—-+—-|/|—-+—-( ) Light

| Light |—-| |—-|

Advantages and Limitations

Ladder Logic offers several strong benefits. Fast setup saves time during installation. Easy modifications help teams adjust systems quickly. Clear diagnostics make it simple to find and fix problems. These strengths make it ideal for many industrial tasks.

However, it does have some limits. It may struggle with complex calculations or advanced programming needs. For tasks that involve data processing or custom algorithms, other languages might work better.

Advantages | Limitations |

Fast and simple setup | Not ideal for complex logic |

Easy to modify and update | Limited in data handling and math |

Clear and visual troubleshooting | Hard to scale for large software projects |

Familiar to technicians | Less flexible for modern programming needs |

Getting Started with Ladder Logic Programming

Start making on/off control projects as a way to become more confident. Check whether you can operate the light and motor by using a switch. These achievements help you see how every part of the logic operates. With experience, you may want to upgrade to better and more advanced settings.

It is important to use simulation tools when practicing with PLCs. They make it possible to check your ideas without using real hardware. You have the ability to observe your program, make updates, and address errors as you go. It helps you progress in your learning and skills slowly and steadily.

FAQ’s

What is Ladder Logic in PLC Programming used for?

Ladder Logic is a programming method in PLC that makes controlling industrial machines and processes easy and clear.

Is Ladder Logic easy to learn for beginners?

Yes, it’s beginner-friendly thanks to its simple, circuit-like layout and intuitive symbols.

Where is Ladder Logic commonly applied?

It’s widely used in factories for automation systems like conveyors, motors, and safety controls.

Conclusion

Ladder Logic remains a trusted tool in industrial automation. Its clear layout, fast setup, and ease of use make it perfect for many control tasks. From simple switches to complex systems, it handles them all with reliable performance.

As technology grows, Ladder Logic still holds its place. It still helps machines run, improves their effectiveness, and lowers the chances of machines breaking down. For anyone working with PLCs, learning Ladder Logic is a smart and valuable step.