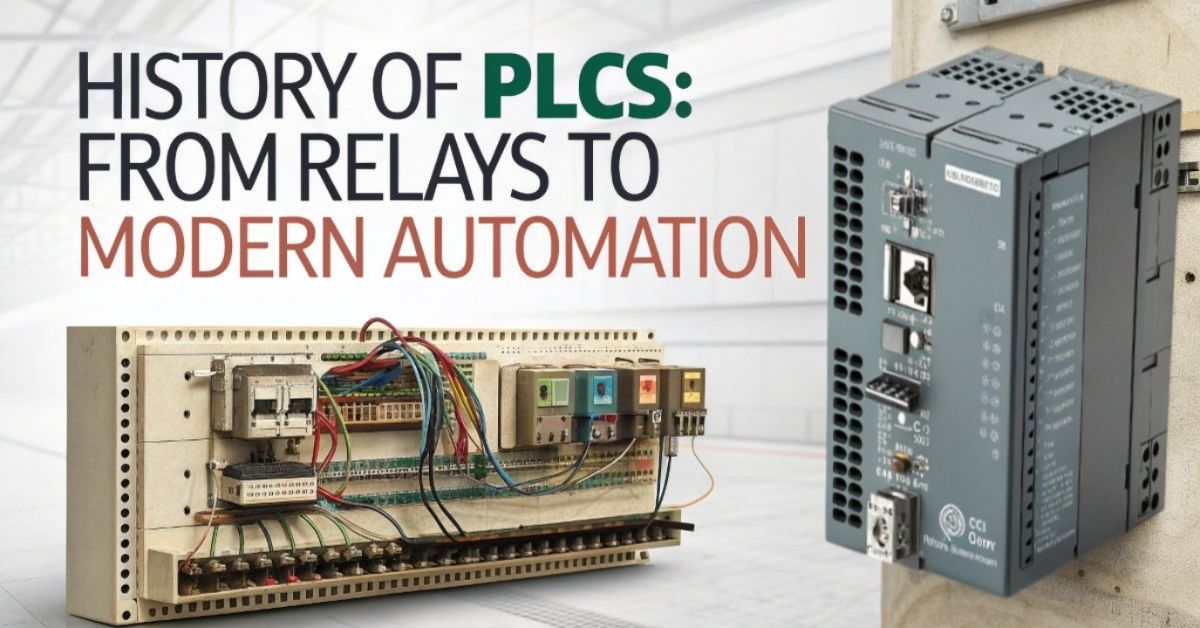

PLCs have established a remarkable progression throughout their development history. The beginning of PLC development started when factories utilized basic relays and mechanical switches. The industrial sector shifted towards progressively smarter control methods because traditional solutions proved inadequate after many years.

The development of the first authentic PLC system, which became a major milestone, came in the late 1960s. The technological advancement since that time has resulted in microprocessors and digital communication as well as touchscreen interfaces. The succession of evolution brought improved automation qualities including greater precision with expanding flexibility and enhanced scalability.

Industrial automation has experienced a complete transformation because of PLCs according to my assessment. Flat programmable devices have replaced the complex panels of wiring that used to be necessary. Industrial production lines are almost entirely powered by PLCs during food processing and car manufacturing.

The Pre-PLC Era: Relay-Based Control Systems

The introduction of PLCs replaced the factory control systems which depended on relay logic. The signaling operation depended on connected timers and switched relays as part of these systems. Mechanical operations ran the entire system as computers did not exist to support it. At that time the solution was considered innovative while suffering from restricted capabilities. The entire control panel needed to be rewritten following any modification. The process of updating required lengthy and expensive work.

The systems proved to have more problems than solutions based on my evaluation. The systems were both large in size and noisy while their main components were wires. The failure of any single unit within the system would cause an immediate stop in the complete process. Relay logic systems became obsolete when factories started to require more complex controls A better solution needed to emerge after this.

The Birth of the PLC in the Late 1960s

Modicon developed the first PLC during the late 1960s. Came into existence as an engineering solution to exchange factory relay networks with a better system. The basic concept behind the innovation proved to be extremely effective. Programming changes enable users to overcome the need of rewiring machines. The development altered everything. The technology reduced both expenses and time expenditure and enabled efficient command process improvements.

The market applications within automotive manufacturing began to show immediate value. The control approach for assembly lines needed both speed in programming changes and dependable control mechanisms.

- Allowed easy changes without rewiring

- Reduced downtime during maintenance

- The technology improved both control system size and operational cleanliness.

- Manufacturing and its facilities operate faster and smarter with this assistance.

- And so the invention formed the foundation that would lead to all subsequent automation developments.

1980s–1990s: Rapid Advancement and Adoption

During the 1980s the technology behind PLCs received major enhancements. The use of microprocessors enhanced their speed while making them smarter. The software developed advanced in complexity while the control mechanisms became simpler to handle. The incorporation of microprocessors resulted in system enhancement leading to greater reliability and power. The updated technologies of factories allowed them to perform multiple automated processes with reduced mistakes.

During the 1990s PLCs emerged in every manufacturing environment beyond automobile factories. Manufacturers in the food industry along with textile companies and packaging facilities started adopting this technology. The true growth of industrial automation took place during this time according to my evaluation. All production facilities sought automatic control solutions because of their fast operation and both correct decision-making and adaptability features.

Software and Networking Revolution

Consequently, it became the standard of PLCs, and allowed the engineers to produce clear and intelligible programs.The programming structure matched electrical circuit operations which enabled engineers to understand it easily. The innovative programming method allowed to attract a larger pool of users. The understanding process of programming required less effort and the approach became more accessible to users.

The introduction of networking technology proved to be the major breakthrough in PLCs. The ability evolved to establish real-time connections with outside systems which allowed them to exchange data. Advanced automation became possible after this breakthrough entered the market. The connection of multiple machines and systems through networking enabled factories to build unified efficient operational networks.

Modern PLCs and Smart Automation

Modern systems show the highest level of intelligence in their generation. Modern PLCs establish perfect connectivity between IoT systems and cloud infrastructure as well as artificial intelligence analytic programs. The combination of different systems through this integration changed automation into its present form. The modern functions no longer restrict to the simple control of machines because it now handles data collection and real-time decision making for efficiency enhancement.

The newest generation of PLCs excel in their minimal size. The relatively smaller dimensions of modern systems accompany their augmented capabilities for motion control combined with data logging abilities. The versatile nature of modernity becomes enhanced because of their compact structure. Advanced manufacturing control technology has become available within smaller packages that deliver better performance combined with factory flexibility.

| Feature | Description |

| IoT Integration | Intelligent data transfer becomes possible through this device which connects PLCs to the internet. |

| Cloud Systems | The system facilitates distant access to storage locations that simplifies observation and management tasks. |

| AI-Driven Analytics | Uses artificial intelligence to analyze data and optimize operations. |

| Motion Control | The system enables users to achieve exact control of machine operational movements. |

| Data Logging | The system maintains records of data that later assists with analytical work and troubleshooting assessments. |

The Future of PLCs in Industry

The upcoming era for PLCs appears highly optimistic. The modification of control systems through this shift will produce more efficient and intelligent systems. Development efforts will center on building systems that remain connected with one another and display adaptive capabilities which operate in real-time. The future factory operations will transform through this development bringing more automated processes alongside operational flexibility.

FAQ’s

What were control systems like before PLCs?

Relays and timers used in their design were hard to change and maintain due to their fixed nature.

Who invented the first PLC and why?

Modicon developed the first PLC in the late 1960s to replace relay logic in the automotive industry.

What is the future of PLC technology in Industry?

PLCs are evolving to support smart automation, integrating with AI, IoT, and real-time data analytics for more adaptive control.

Conclusion

Early PLC technology used relays as its core components. Modern automation relies on PLCs because these devices have developed into robust adaptable tools which provide automation capabilities. Industrial development through this evolution has produced more efficient and reliable systems.

Technology advancement will result in gaining increased intelligence while becoming more capable. PLCs stand as fundamental controllers that will direct manufacturing development in the forthcoming years. Factory automation will progress at higher speeds because of this development which will transform production facilities into faster and more efficient systems.