A Programmable Logic Controller serves as a compact computer device which directs both machines and processes. The device accepts input signals then processes them through its programmed instructions to establish output signals that control equipment. The PLC functions as the control system which operates various automated devices starting from robots and industrial conveyors to traffic signal systems.

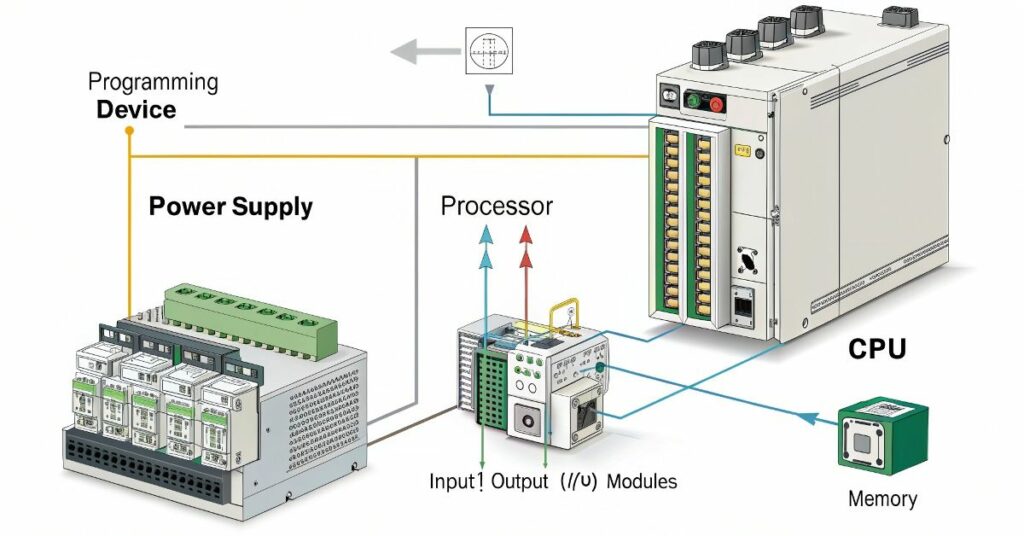

Machines can execute their tasks repeatedly by knowing exactly what operations to perform but without creating any sound related complaints. That’s the magic of a PLC. The system listens to sensor data before executing commands and progressing outputs to machines. A processor and memory together with input/output modules and power supply operate from within its interior. Simple parts, powerful results. The interlocking components create a perfect system function which operates identically to mechanical timepieces. Let’s break it down.

What Is a PLC and Why It Matters?

Let’s talk in detail now. Programmable Logic Controllers function as miniature computers made to execute industrial projects. The machine resides within industrial facilities to perform silent tasks of machine control. A digital brain now takes the place of traditional wiring techniques and timers. I consider this invention as one of the most significant breakthroughs in automated systems. The entire production workflow in both car manufacturing facilities and bottling lines operates safely thanks to PLCs.

Operations generate their own actual enchantment through its operational approach. The PLC system observes input data such as sensors before performing a speedy evaluation process. After computing the logic system it selects appropriate actions that result in proper outputs. Through its processing the system enables motors to start up and valves to open while illumination occurs. This system continuously operates without problems throughout both day and night. The reason matters is because they allow operations to continue in a perfect flow without any interruptions.

The Core Components of a PLC

Every PLC consists of four essential operational parts including CPU, input/output modules, memory and power supply. The CPU performs as the decision-making authority in the system. The inputs receive real-time measurements from physical systems by sensors that detect heat. Outputs execute the operational commands such as turning on a fan unit. The PLC uses Memory to store its logical instructions much like its operational blueprint. A power supply maintains all operations since it serves as the fundamental foundation of every system. According to my assessment the operating mechanism represents a smart design because each component functions within its designated role to maintain system stability.

The PLC Scan Cycle Explained

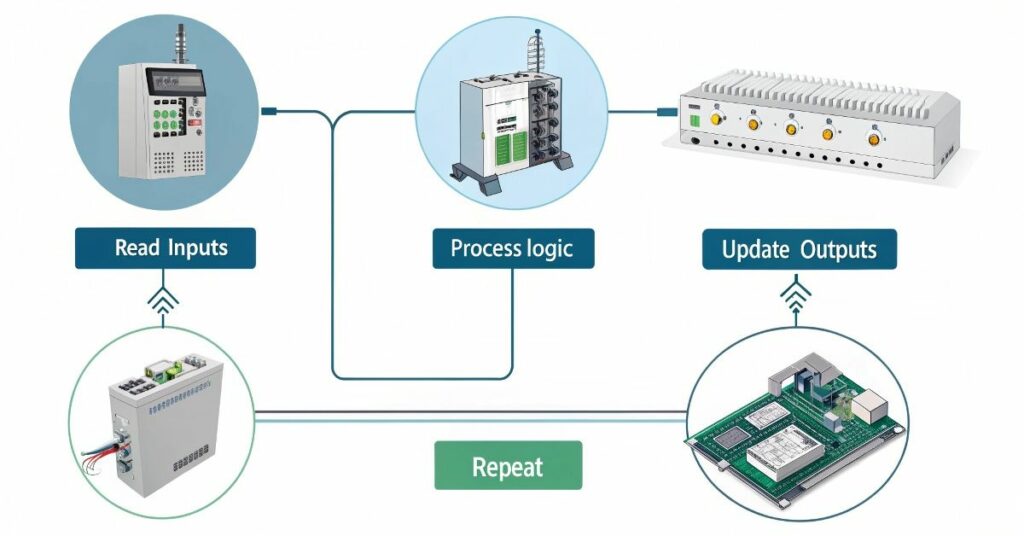

The PLC operates its scanning sequence automatically. The programming starts by reading inputs and then proceeds with processing logic before updating outputs before it restarts. No breaks, no lazy days. Machines perform their response nearly at the moment as this cycle continues to repeat itself. The functioning pattern resembles recipe preparation because operators need to verify ingredients while preparing dishes for multiple service rounds.

The continuous looping mechanism maintains precise operation of all systems. Machines respond immediately to any detected change with the help of this process. According to my evaluation the dependability stems from their steady operation as they never pause. Each step in this system functions in the following manner:

- Read Inputs – Check sensor signals, switches, or buttons.

- Process Logic – Decide what should happen based on the program.

- Update Outputs – Send commands to devices like motors or lights.

- Repeat – Go back to the top and do it all over again.

Input and Output Interactions

The input modules serve as sensors that give feedback to the PLC by acting as its detection system. The input modules collect data signals that arise from monitors and buttons and switches on a control panel. The PLC receives system information through this data. Is the door open? Has a tank reached its level? As far as automation talks go, inputs function as a crucial component similar to the contextual flow of information which keeps the system updated about current system operations.

Then come the output modules. The operation’s muscles function as output modules in the system. The PLC sends instructions to these modules which activates machinery through motors as well as motors and lamps and safety alarms and valves. Output modules serve as automation’s action heroes by delivering their results once called upon after remaining unobtrusive before execution.

Here’s a quick glance:

| Type | Example Devices | What It Does |

| Input | Sensors, switches, buttons | Sends real-world data to the PLC |

| Output | Motors, alarms, lights, valves | Acts on the logic and controls equipment |

Programming Logic and Control Instructions

The programming language used by PLCs includes ladder logic and function block diagrams to carry out operations. The language features basic appearances yet delivers an outstanding performance. I consider Ladder Logic user interfaces as modern versions of traditional electrical wiring outputs. Each instruction within exists as a rule that triggers specific actions according to particular input conditions. When button A is pressed while door B is closed the should start motor C. Programming resembles education of machine chess abilities because it analyzes positions, generates a move and repeats this sequence flawlessly.

Real-Time Decision Making in Action

Programmable Logic Controllers operate at higher speeds than human thought processes could achieve. The devices read incoming signals before following predefined operational rules to produce quick decisions. The system operates similar to an uninterrupted traffic control monitor that functions constantly. The launch of an operation starts when one sensor activates which causes an immediate effect. The rapid decision-making processes enable equipment to operate smoothly as a well-functioning system. And the best part? No one has to babysit it. The PLC maintains system operation at all levels including complex systems because it performs all necessary thinking automatically without requiring rest time.

FAQ’s

Context of PLC execution focuses around the scan cycle actions?

The loop executes the sequence of reading inputs followed by logic processing which leads to output updates before repeating itself within milliseconds.

Can PLCs handle multiple tasks at once?

Yes, they can manage several operations simultaneously with precise timing and control.

A PLC has the capacity to use different types of input and output signals?

The system can accept inputs through buttons as well as sensors and generate outputs by managing motors, valves or alarms.

Conclusion

The size of PLCs remains small while their operational role attains significant importance. These devices maintain control over machines alongside rule execution while providing safe operation systems. The devices manage activities which humans commonly overlook while performing quick processing and input interpretation followed by instant decision-making operations.

The silent superhero status belongs to in the world of automation. The setup process allows PLCs to operate automatically from day to day without any complications. The time, accuracy and dependability requirements of your system should be addressed with a PLC solution. Simple as that.