PLC Programming Language choice can make or break your automation project. Since there are so many possibilities, it can be hard to choose. However, picking the correct language makes it easier to prepare, reduces mistakes, and accelerates the outcome. If the first part is clear, the rest of the process follows easily.

Every project is set up with its own set of goals. Factory systems with many parts don’t have to use the same language as simple conveyor belts. Languages vary in their speed, ease of using, or how easy they are to fix problems in. Picking a language that fits your project helps you save time and remain calm.

Using the right language helps you handle the game better and see better results. It makes your system work faster, in a safer way, and with greater reliability. In addition, it is simpler to handle and increase over time. Choices you take today will have a positive effect on your outcomes in the future.

Table of Contents

ToggleUnderstand the Basics of PLC Programming Languages

PLC languages follow standard rules set by IEC 61131-3. This means developers around the world use a common structure. It helps reduce confusion and improves teamwork. No matter the brand or software, the basics stay the same. This makes training easier and boosts project efficiency.

Each language fits different needs. Ladder Logic is great for electricians. Structured Text is an effective tool for handling complicated math and data. Some are better for speed, others for easy visuals. Different industries and users prefer what suits their workflow best. Choosing the right fit leads to smoother, faster results.

Assess the Project Scope and Requirements

Start by looking at how complex your project is. Think about how fast the system should respond. Decide how much control you need over each part. A simple machine may not need advanced logic. But a high-speed or multi-layered system will. Clear answers help guide your language choice.

Next, check if the language works with your hardware. Make sure it can grow with future changes. Easy updates and streamlined maintenance save time later. Some languages are better for long-term use. Planning ahead keeps your system strong, flexible, and ready for what’s next.

Compare the Main PLC Languages

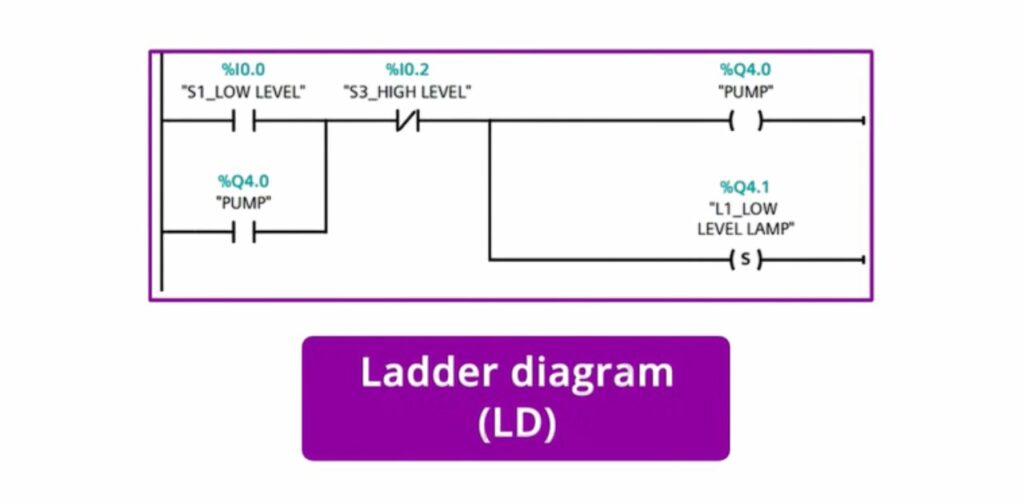

Ladder Logic is easy to understand and use. It looks like electrical relay circuits, which makes it perfect for electricians. Many systems and industries support it. It’s great for simple tasks like turning motors on and off. Because it’s visual, troubleshooting is also quicker and more straightforward.

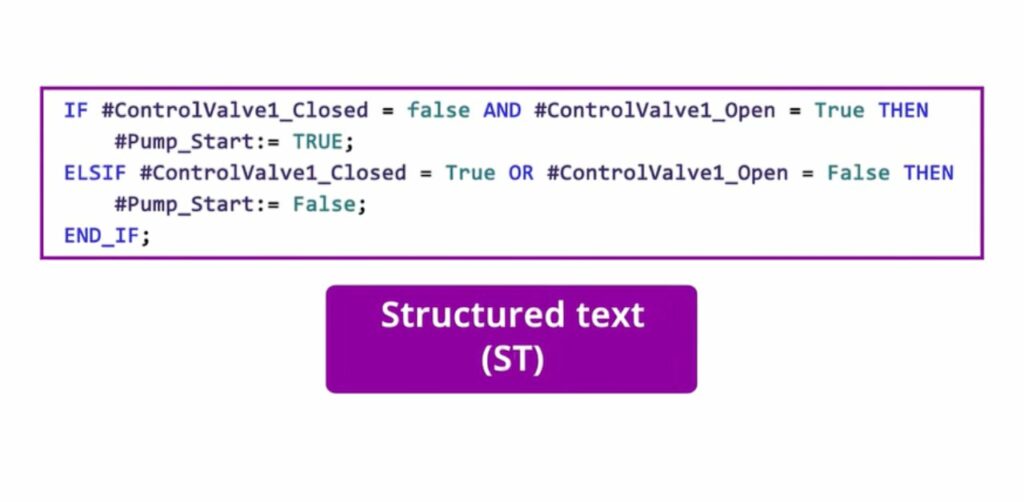

Structured Text gives you more control. It handles complex math, data, and decision-making better. It is best used when there are a lot of variables involved in the system. Programmers who know traditional coding will feel at home. While it’s not as visual, it’s powerful and flexible for advanced tasks.

PLC Language | Best For | Key Strength |

Ladder Logic | Electricians, simple systems | Easy to read and troubleshoot |

Structured Text | Advanced logic, complex tasks | High flexibility and power |

Match Language with Team Skills and Workflow

Pick a language your team already knows well. When people feel confident, they work faster and make fewer mistakes. If your team has electrical experience, Ladder Logic may be the best fit. For teams with coding skills, Structured Text could be more efficient. The right match saves time and boosts teamwork.

Also, think about how your team tests and maintains programs. The language should fit your daily workflow. Clear structure and smooth debugging make a big difference. Good documentation keeps everything organized and future-ready.

- Choose a language your team understands

- Make testing and debugging simple

- Use a style that supports clear documentation

- Avoid steep learning curves

- Keep long-term support in mind

Factor in Industry Standards and Support

Some industries stick to certain PLC languages. This is often due to old systems already in place. For example, manufacturing plants may rely on Ladder Logic. Water treatment or energy sectors might use Structured Text. Sticking with these standards helps avoid costly rewrites and training.

Support also plays a big role. Choose a language backed by strong vendor help and regular updates. A large user community means more tips, tools, and troubleshooting advice. This makes learning easier and keeps systems running smoothly over time. Reliable support ensures long-term success.

Choose with Future Growth in Mind

Pick a language that grows with your technology. It ought to be compatible with modern technologies and programs. As automation evolves, your programs should keep up. A flexible language makes it easier to add new features or connect with other platforms.

Also, think long-term. The language should stay reliable as your system expands. It should be flexible enough to cope with new needs without requiring big changes. Future-ready choices save money, reduce downtime, and keep operations strong over time.

FAQ’s

How can I pick the proper PLC Programming Language for my project?

First, check what is needed for your project, what your team is capable of, and what is common in the industry to make the best choice.

Is Ladder Logic still used in today’s automation?

Yes, it is popular because it is straightforward, well-presented, and gives strong help in industrial areas.

Can I change the PLC language I am using during the project?

While it can be done, it could mean using more time, effort, and making some system changes on the platform.

Conclusion

Picking the best PLC programming language is important for a successful automation project. The most suitable solution makes your system easier to construct, run more efficiently, and keep maintained. It helps save time, avoids mistakes, and increases the team’s confidence.

Keep your targets, the abilities of your team, and future aspirations in mind. Select a PLC programming language that fits with your resources, your business area, and what you want to do in the future. If you take the right decisions now, your business will operate without problems in the future.