Water treatment automation with PLCs is changing how we handle clean water. I believe that the use of programmable logic controllers in water treatment and distribution improves the overall efficiency and speed of operations. That is why the systems allow you to adjust the controls that monitor the pump and manage filtration as needed.

Automation, in my opinion, raises the bar for efficiency. And at the same time, it also increases productivity and ensures that everything runs smoothly. If downtime is reduced, the process is more consistent, and therefore the water treatment plant and resources can be managed without wasting time.

Human errors can cause major problems in water systems. We can say that automation provides real peace of mind. And it creates better ways to run things, and finds problems faster, helping to keep everything organized. And the result is this? Better safety, higher quality service, and easier operations.

Introduction to PLCs in Water Treatment

PLCs (programmable logic controllers) play a big role in modern water treatment plants. They take care of the pump, filter, and chemical dosing tasks very quickly and precisely. I think they make complex tasks faster and easier. Instead of guessing, you can use live data to make better choices for operators.

I think the move from manual to programmable logic is a real breakthrough. It brings more accuracy and reduces errors. It’s a process step that runs the same way every time, which keeps the system stable and secure. And it makes a huge difference in how well the plant performs.

Key Benefits of Automation in Water Systems

Automation makes water systems better and faster. I think it reduces wasted time and keeps things running smoothly. When these systems are more efficient, there is less downtime and fewer failures. It also helps meet safety and environmental regulations more easily, which is a big win for any plant.

In my opinion, PLCs take things even further with real-time monitoring and data logging. You can see what’s happening at every step and fix problems before they grow. This kind of insight builds trust and keeps teams more accountable.

Here’s what automation with PLCs offers:

- Faster response to system changes

- People do less manual work and make fewer mistakes.

- System logs that track real-time performance.

- Improved chances to follow water quality standards.

- Better decision-making with real-time data

Core Functions of PLCs in Water Purification

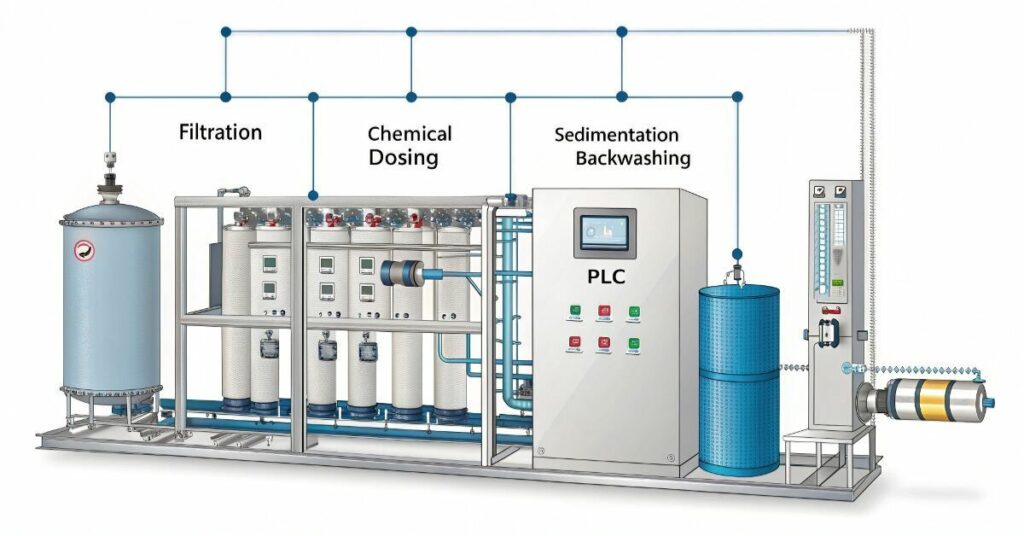

PLCs are responsible for quickly and accurately managing key parts of the water purification process. All together, they control filtration, chemical dosing, sedimentation, and backwashing. I think this type of control keeps everything balanced and efficient. Every step happens at the right time, in the right way, without any delays.

It is also important to have automated alerts and safety features. These alert operators to things going wrong and stop problems before they escalate. They help ensure that the water is safe and of good quality. Clean and safe water starts with this smart system.

Integration with SCADA and Remote Monitoring

PLCs integrate well with SCADA systems to allow for complete control from one place. I think this kind of setup makes it easier to see what’s happening across the entire plant. Operators can track every part of the process in real time and react fast when something changes.

In my opinion, remote access takes that control even further. Technicians don’t have to be on site to look at the system, making it quicker and easier for them. They can fix issues quicker, even before someone’s on-site. That kind of flexibility keeps everything running strong and steady.

Real-World Applications in Distribution Networks

PLCs are used to control and manage pump stations and the pressurized zones in municipal water networks. I think this makes sure that water flows smoothly to homes and businesses, even when demand changes. It keeps the whole system in order and working well with no problems.

They ensure that the appropriate quantity of treated water is delivered to the users even when the demand either increases or decreases. Through this, there is always adequate supply of water for all whenever needed and none is lost when the demand is low. Such control makes the water distribution system reliable and cheap.

Key Functions of PLCs in Distribution Networks

| Function | Description |

| Pump Station Regulation | Controls movement of water and its pressure in the distribution system. |

| Reservoir Level Monitoring | Makes sure reservoirs have enough water for everyone’s use. |

| Pressure Zone Management | Changes water pressure where needed so the flow stays the same. |

| Flow Coordination | Alters the flow of treated water to meet the people’s needs and end waste. |

Future Trends and Sustainability in PLC Automation

New tools offered by AI and IoT are making water management smarter. I believe that these technologies are assisting PLCs to anticipate needs and alter operations when things go wrong. With such a predictive power, efficiency increases and systems continue working well. It is as if you have a planner for you and thus you save time and effort.

Cutting waste and costs is possible with sustainable automation. Optimizing processes with PLCs means there is less energy used and less water lost. As time goes by, this method saves you lots of money and is also good for the earth.

FAQ’s

What is Water Treatment Automation with PLCs?

PLCs are used in Water Treatment Automation to automatically keep track of, control, and improve water purification and distribution systems.

Why are PLCs important in water treatment plants?

PLCs provide effective control, reduces human mistakes, and ensure the quality of water with automated systems.

How do they make the flow smarter, faster, and more reliable?

They watch pumps, see how full the reservoirs are, and manage water flow to suit demand.

Conclusion

PLCs are changing how we handle water treatment and distribution. By being precise, reliable, and efficient, they support easy management of complicated processes. By using automation, water plants are able to work both more safely and more efficiently, meeting all requirements and customer needs.

The prospects for the PLCs in water management only get better. AI, IoT, and sustainable approaches will help to make the businesses perform better and waste less. These treatment systems will become more efficient and environmentally-friendly with further development of technology.