Plc is a combination of software and hardware, which is connected with field devices and control the operation according to given programming while the scada is only a software who provides the help to control and supervise this process as well as acquire the data record.

Functionality of plc

Each plc brand has its own software which provide help to program and configuration to plc for different operations. on the other hand, all the field devices like (sensors actuators and vfds) are connected with plc through different types of communication protocol like mode bus. In simple words Plc act like a mind who takes the analog and digital signals through field devices and gives the instructions according to programming while field devices do the work as eyes and hands, these devices collect the data from field and execute the operation according given instructions.

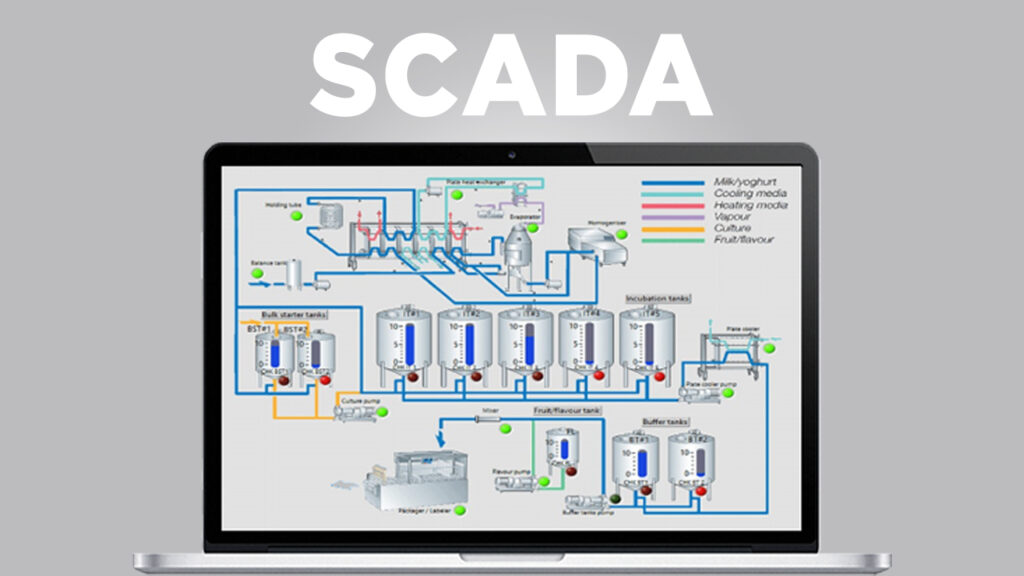

Scada functionality

Scada is just a software who connected with plcs controllers,its provide the graphical view so we can supervise the process through it and gives access to pass the different instructions to controllers. Moreover scada system equire the data form these controllers and save it in connected database, scada system also showes this data in different types of charts, where we can analyze the data in very simple way.

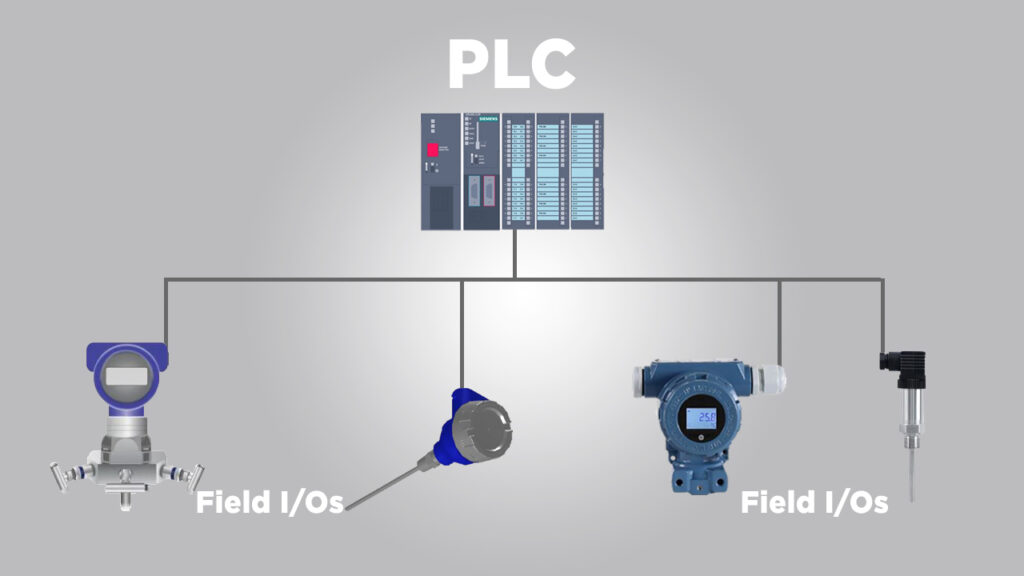

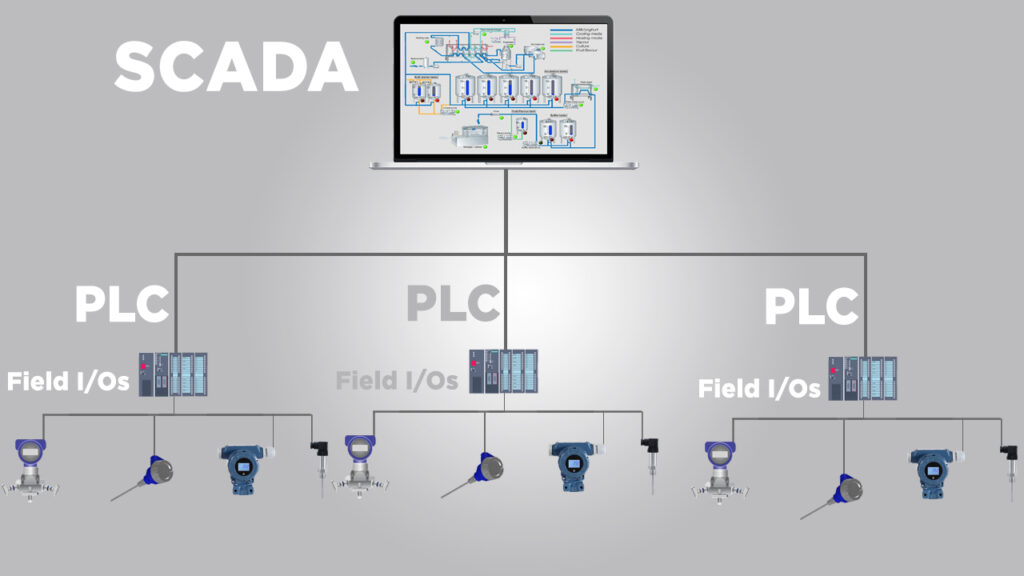

What is the role of PLC in SCADA?

In scada system plc use like a controller which has the programming file In its memory and plc perform the operation according to its programming logic. plc also receives the digital and analog signals from field with the help of field i/os. Other than that plc send this data to scada system, where scada show this data in graphic form. In simple words, in scada system lot of plcs are working in same time which are controlling different processes in plant, we can not monitor all plcs directly so we use a scada software to supervise, control and record the data.

Can PLC work without SCADA?

Plc can work without scada because wherever we don’t need of graphical view, data record or control, plc can be used without scada it will perform its operation according to logic but scada system useless without plc because in scada system plc is main unit which control by scada. If we shall neglect the plc from this system scada system has not any use.

Which is better PLC or Scada?

There is no comparison in between plc and scada regarding superiority because both are perform in different domain both are important in industrial automation and both need to be learned to become successful engineer.

| PLC | SCADA |

| Hardware device which used to control or automate different process and machinery. | SCADA is a software which provide graphical view, supervisery control and , record te data. |

| Plc does work in lower stream. | Scada does work in upper stream. |

| Plc receive input and output signals from field i/os to control related machine or process. | Scada communicate with different plc in same time and provide graphical view controlling process. |

| The different programming languages (ladder logic, FBD) use to programe the plc. | In scada different graphical libraries are sued to make the graphical view. |

| Plc use for real time control the process or machine by programming. | Scada use for real time monitoring, store the data for analyzing and take the corrective actions. |

| Plc is used for specific machine and process | Scada use for hole plant. |

Which should I learn first SCADA or PLC?

In industrial automation plc is a first step to learn, you can start from plc programming because Scada is come in upper layer of automation. PLC hardware understanding, plc wiring methods and plc basic programming shell be the initial steps of your dream journey then you can go ahead for scada system .

FAQ’s

Can SCADA work without PLC?

PLCs are used to directly control and automate industrial machinery and processes. They execute control algorithms and interact with physical systems like motors, valves, pumps, sensors, and actuators.

SCADA, on the other hand, is primarily used for monitoring and supervising those processes, collecting real-time data, and allowing operators to control the processes remotely.

PLC-Integration: The PLC provides real-time, low-level control, while the SCADA system provides high-level monitoring, data visualization, and control.

What is the difference between PLC HMI and SCADA?

A PLC is a specialized computer used to automate industrial processes. It controls machinery and processes based on input from sensors, feedback from the system, and pre-programmed logic.

An HMI is the user interface through which operators interact with a system, allowing them to monitor and control the PLC-controlled process. It’s typically a graphical display that provides a visual representation of the system.

SCADA is a centralized system that provides high-level monitoring and control over large, often geographically dispersed, industrial operations. It collects data from sensors, PLCs, and RTUs (Remote Terminal Units), and provides operators with comprehensive oversight.

Comments are closed.