PLC Programming is changing fast. The introduction of object-oriented programming and AI Email addresses both system intelligence and user-friendly management needs. The modern automation developments through these changes enable better flexible automation systems.

Enhanced control systems have evolved from optional to necessary elements which must be implemented. The transformation of PLCs to correspond with industrial requirements for present times stands at the forefront of manufacturing industry focus.

Throughout the subsequent period we will gradually enter a new automation age. The pace of technological progress requires continuous learning of new instruments and new methodological approaches for advancement. A new wave in automation technology will arrive rapidly during the upcoming years.

Introduction to the Evolving Landscape of PLC Programming

The old methodology of PLC programming has ceased to meet industry needs. The current industrial speed requires outdated techniques to evolve. Greater machine functionality is a prerequisite when they communicate rapidly with digitization to carry out sophisticated actions. The leading reason engineers shift from rigid ladder-based logic according to my perspective is the following fact. Industrial operators select modern adaptable approaches that help them maintain their speed in production.

The modern ways of building automation PLC systems are defined by the powers of AI and IoT and edge computing technology. These technological instruments are bringing additional strength and accuracy during factory operations. Modern technology delivers better data points that enable smarter decisions which makes automation systems achieve unprecedented intelligence.

Rise of Object-Oriented Programming in PLCs

The development of control PLC systems undergoes significant changes because of object-oriented programming (OOP). Problem solvers appreciate the strongest asset of the modular design of OOP. Code blocks are ready for reuse without requiring complete rewrite operations. Clear logic while faster updates and decreased errors exist as the result of OOP implementations. OOP provides systems with complex requirements which become easier to scale up and maintain.

Additional PLC platforms start to embrace this technology. The programming language is implementing OOP features as part of its development to enhance both speed and intelligence. Engineers now achieve higher efficiency and develop better initial systems through this transition in programming practices.

Key benefits include:

- Code blocks deploy available time saving capabilities

- Faster updates across multiple machines

- Better teamwork with organized code modules

- The systems must accommodate your organizational expansion needs

The Role of Artificial Intelligence in Automation

The modern PLC introduces a transformation through artificial intelligence technologies. One of the greatest advantages of the use of AI in the PLC systems is their ability to predict maintenance needs in advance. The system detects malfunctions before machines fail therefore saving time and costs. The smart systems facilitate decision-making that becomes better as well as faster. The innovative application of artificial intelligence possesses exceptional levels of intelligence for industrial automation PLC systems.

The technology enables systems to learn and readjust their operations while data is active. The implementation of control procedures benefits from improved accuracy and efficiency because of it.

The difference it brings is clear:

| Feature | Traditional PLCs | AI-Integrated PLCs |

| Decision-making | Based on set rules | Data-driven and adaptive |

| Maintenance | Reactive | Predictive and proactive |

| Process optimization | Manual tuning | Automated improvements |

| Flexibility | Limited | Highly adaptable |

Connectivity and IIoT Integration

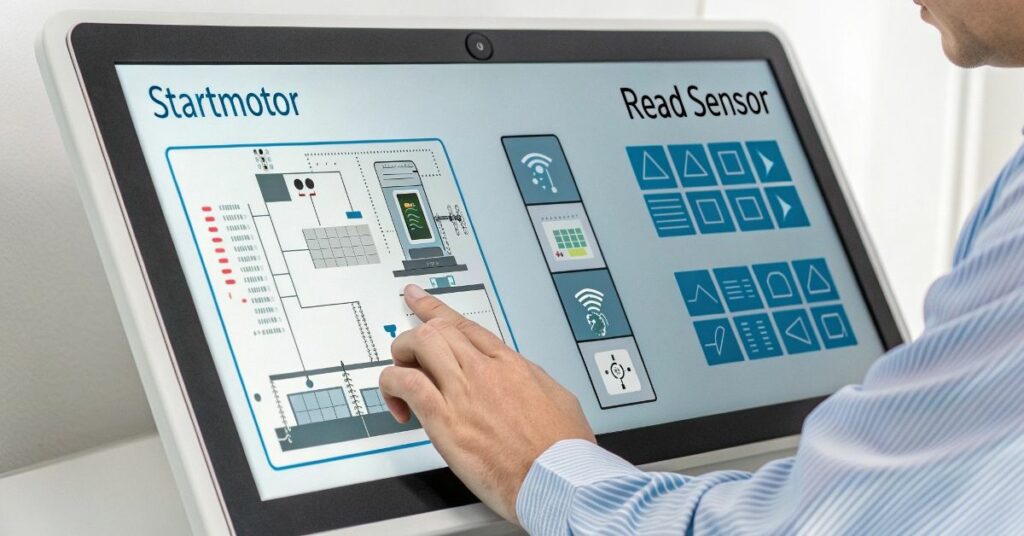

Modern PLCs operate independently within industrial control. The IIoT ecosystem now recognizes traditional PLCs as essential contributors to its operations. Modern systems have integrated abilities for connection with sensors and cloud platforms as well as other machines. The industrial revolution has resulted in smarter factories that respond better to operations.

Enhanced device-to-device data communication makes all operations operate more efficiently. The smart connection stream improves decision timing while decreasing time-lags. The integration marks a significant advancement that brings automation systems one step closer to data-based manufacturing.

Cybersecurity Challenges in Modern PLC Systems

With increasing PLC network connections the security vulnerabilities also increase. Cybersecurity measures are a necessity for every organization because now protection of critical infrastructure is mandatory. Criminals exploit these systems to launch interferences with production systems or retrieve valuable data. Unprotected connected devices amount to every possible entry point in my opinion.

Survival in the industry requires increased attention to safety measures. Accurate protocols and standards currently develop stronger safeguards for systems. Update cycles and access controls together with firewalls have become necessary components for security management. Preventing threats represents only one aspect of Cybersecurity because the main objective remains to establish trust across all automated systems.

Preparing for the Future: Skills and Tools for Tomorrow’s Engineers

Present-day engineers must possess more than traditional techniques. Technology professionals need to master object-oriented programming and AI as well as networked systems according to my assessment. The next automation revolution will develop from these specific regions. As per my view, remaining relevant requires both a curious state of mind and flexible adapting abilities.

The profession undergoes a simultaneous transformation while new technological resources shape the work practice. Future engineering roles require active knowledge and experience working with contemporary PLC platforms as well as smart software applications. People who discover emerging technology in advance will take the leadership position. Engineers who begin thinking strategically while building toward their visions will determine the future.

FAQ’s

Why does PLC Programming stand as a crucial element in developing its future direction?

The future of PLC programming will include next-generation combinations between artificial intelligence systems and object-oriented programming features to boost automated process efficiency and linkages and flexibility capabilities.

Which transformations in PLC development result from object-oriented programming?

The modular approach of OOP creates reusable code structures which simplify PLC program management and scaling and debugging procedures.

Current PLC systems integrate AI capabilities which power their operation?

AI enables predictive maintenance, adaptive control, and real-time decision-making within industrial automation systems.

Conclusion

PLC programming has an optimistic outlook with multiple promising possibilities ahead. The industry will improve through the movement toward flexible smart PLC systems. Enhanced connectivity along with AI integration has no boundaries regarding what can be achieved. Engineers and businesses should adopt these upcoming changes because it will put them in front of industry competition.

Basic principles of technology development require us to update our abilities and methods. Adaptiveness combined with knowledge acquisition serves as the main factor leading to success. The industry continues to expand rapidly so individuals who embrace this growth will become leadership examples. Our role consists of developing automation systems that will define the technology’s promising future.